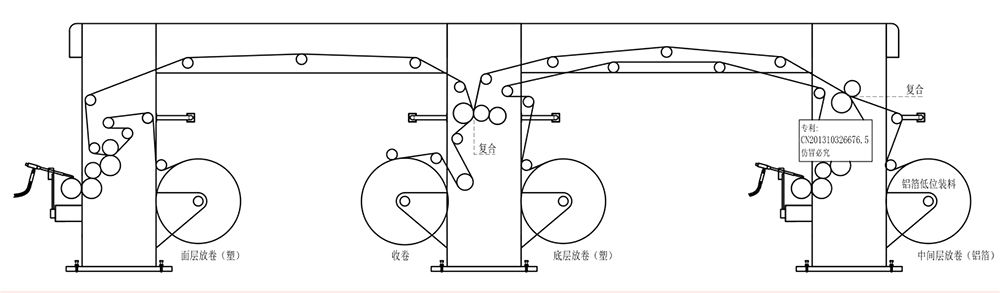

Solventless Laminator TRI-1300A

Three-layer lamination machine for use with solventless adhesives, shorter web path without undesirable adhesive penetration

Our SINSTAR three-layer solventless lamination machine is mainly applied to produce flexible packaging laminates for the a multitude of market sectors including food, pharmaceuticals, personal care items, anti-static materials, insulation materials, building materials and decoration. As the lamination process does not involve any solvents and eliminates any possible penetration of adhesives through the webs, the solventless lamination machine can be a very suitable choice for manufacturing high-quality aluminum foils and packaging laminates free from adhesion of rewound layers. The solvent-free laminator is also capable of producing packaging films featuring perfect protection against moisture and any transport of matter to guarantee the best freshness of packaged goods. If you are considering refined packaging for luxury cosmetics or eco-friendly packaging, this solventless lamination machine will also be a satisfying option for that.