In the personal care and cosmetics industry, the production of label films and packaging films for various products, including cosmetics, bath/shower product packaging bottles, over-the-counter drugs/nutritional supplements, baby care items, and eye care solutions, relies heavily on laminated plastic films. These films play a crucial role in providing waterproofing, tamper-evidence, and printable functionality. Moreover, the printed text and images must meet high-definition standards to uphold the image and branding of diverse personal care brands. This necessitates specialized technical support and advanced plastic film lamination equipment.

Since 2005, we have been dedicated to providing laminated packaging solutions tailored to the unique needs of pharmaceutical industry companies. With over a decade of experience in manufacturing solventless lamination equipment and a deep understanding of the personal care packaging sector, we offer comprehensive solutions. Our solventless machines seamlessly integrate with other printing and cutting equipment, creating plastic packaging production lines tailored to the varied needs of personal care film manufacturers. These production lines are capable of generating label films with diverse specifications, including shapes, thicknesses, waterproofing levels, and tamper-evidence features. Moreover, our solventless laminator places a strong emphasis on the well-being of equipment operators during the production process, ensuring a safe working environment.

Our commitment to user-friendliness extends to customizing language settings on the solventless laminators, aligning with the location of the client company. Incorporating IoT technology enhances remote maintenance and troubleshooting capabilities, enabling packaging material manufacturers to prioritize product production while reducing operating and maintenance costs. With over a decade of development, our lamination equipment has achieved global recognition, exported to more than thirty countries and regions, and trusted by over 2500 companies.

In the personal care packaging industry, if you require a solventless laminating machine, we recommend ours.

-

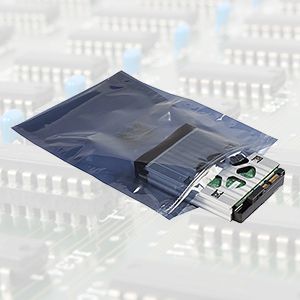

- WRJ i9-1300A (2-layer Lamination) Simple operation is the ultimate principle The solventless lamination machine is primarily designed for the production of flexible packaging by bonding two layers of flexible films with solventless adhesive. It joins together different flexible packaging webs to create a two-layer structure as the packaging laminate for various industries such as food, pharmaceutical, personal care & cosmetic, anti-static packaging, EMI shielding, construction, decoration & renovation, and more. More Info

-

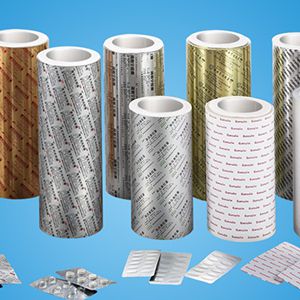

- WRJ Fi9-1300A (2-layer Lamination) Consuming less power, lower operation costs The solventless laminator provides the eco-friendly solution of solvent-free adhesive coating while ensuring precise coating weight consistency, thus serving as a popular choice for the manufacturers of flexible laminates that are suitable for product packaging. The lamination machine is commonly used to produce flexible packaging that consists of two substrates (generally 7µm -120µm in thickness) made of BOPP, PET, Nylon, CPP, PE, VMPET, VMCPP, PVC, etc. More Info

-

- TRI-1300A (3-layer Lamination) Aluminum foil, low loading, short path, no adhesive penetration Our SINSTAR three-layer solventless lamination machine is mainly applied to produce flexible packaging laminates for the a multitude of market sectors including food, pharmaceuticals, personal care items, anti-static materials, insulation materials, building materials and decoration. More Info

-

- SUPLOCK Solventless Laminator Non-stop transferring of material rolls SUPLOCK - the ultimate solventless laminator upgraded for the flexible packaging industry! Powered by renowned German electrical control system like Siemens, SUPLOCK has achieved higher levels of automation for its solvent-free laminating machines. Besides, the innovative duplex workstation design of SUPLOCK keeps your production running smoothly, permitting significantly higher efficiency. More Info

-

- OUTDRY Solventless Laminator Breathable and waterproof The OUTDRY solventless laminator is primarily designed for producing waterproof and breathable films. The breathable films made by our laminators allow moisture to escape easily while preventing liquids from entering. This solventless laminating machine is suitable for manufacturing products such as protective clothing and baby diapers. More Info

If you have specific requirements on these five solventless lamination machines, please contact us immediately, we also offer customization services.