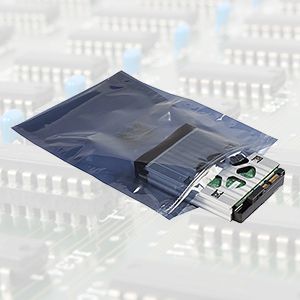

EMI shielding & insulation industry features various needs for laminators. Cable manufacturing is one of them. The cable manufacturing industry relies on foil tape for various critical functions, including cable insulation, signal shielding, and thermal insulation. However, the production of this foil tape involves intricate processes and techniques.

To cater to the diverse requirements of users, we specialize in producing a wide range of EMI shielding materials. These materials feature different thicknesses of substrates, such as PET film, PP film, PI film, PPS film, and more, combined with various types of metal materials, including copper, aluminum, and alloys. The intricate process involves layering these materials in configurations of two, three, or five layers to achieve precise signal shielding or insulation effects. This level of precision requires a high degree of specialization.

As a professional supplier of solventless laminators, we offer all-encompassing solutions to the cable manufacturing industry. Our approach places a strong emphasis on environmental sustainability and the safety of our personnel. This commitment to responsible manufacturing practices has garnered recognition and appreciation from cable manufacturers worldwide.

In the EMI shielding & insulation materials industry, if you have a need for solventless laminating machines, we recommend ours.

-

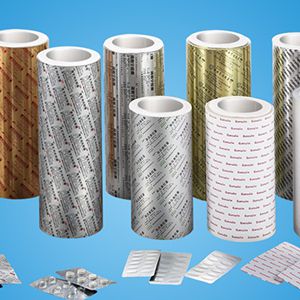

- WRJ i9-1300A (2-layer Lamination) Simple operation is the ultimate principle The solventless lamination machine is primarily designed for the production of flexible packaging by bonding two layers of flexible films with solventless adhesive. It joins together different flexible packaging webs to create a two-layer structure as the packaging laminate for various industries such as food, pharmaceutical, personal care & cosmetic, anti-static packaging, EMI shielding, construction, decoration & renovation, and more. More Info

-

- WRJ Fi9-1300A (2-layer Lamination) Consuming less power, lower operation costs The solventless laminator provides the eco-friendly solution of solvent-free adhesive coating while ensuring precise coating weight consistency, thus serving as a popular choice for the manufacturers of flexible laminates that are suitable for product packaging. The lamination machine is commonly used to produce flexible packaging that consists of two substrates (generally 7µm -120µm in thickness) made of BOPP, PET, Nylon, CPP, PE, VMPET, VMCPP, PVC, etc. More Info

-

- TRI-1300A (3-layer Lamination) Aluminum foil, low loading, short path, no adhesive penetration Our SINSTAR three-layer solventless lamination machine is mainly applied to produce flexible packaging laminates for the a multitude of market sectors including food, pharmaceuticals, personal care items, anti-static materials, insulation materials, building materials and decoration. More Info

-

- MEGAOHMN Solventless Laminator Zero emission, environment friendly, no oven, saving power MEGAOHMN, a game-changer in solventless lamination! Unlike the SINSTAR and SUPLOCK solventless laminators designed for flexible packaging films, the MEGAOHMN laminating machine is specially crafted for laminated materials like flexible multi-later insulating materials, including PET, PVC, PS, PP, and more. MEGAOHMN solventless laminator can be applied to top-notch insulation in the electrical, electronic, and various industrial sectors requiring flexible insulation laminates. More Info

If you have specific requirements on these three solventless lamination machines, please contact us immediately, we also offer customization services.